3-axis vertical turning center

The machine equipment of the sitting structure adopts a special design concept, combined with the joint surface of the glue-injected column and the base, which effectively absorbs heat energy and isolates vibration. The equipment adopts vertical shaft main transmission mode, the gear in the spindle box is treated by quenching process, and has the function of two-speed stepless speed change. At the same time, the encoder is configured in the center of the spindle to realize the cutting operation of constant linear speed.

Key words:

Category:

VTL Series

Product Details

The machine equipment of the sitting structure adopts a special design concept, combined with the joint surface of the glue-injected column and the base, which effectively absorbs heat energy and isolates vibration. The equipment adopts vertical shaft main transmission mode, the gear in the spindle box is treated by quenching process, and has the function of two-speed stepless speed change. At the same time, the encoder is configured in the center of the spindle to realize the cutting operation of constant linear speed.

The beam of the machine can be moved arbitrarily according to the needs within the stroke range of the column. This humanized design greatly improves the convenience of operation. In addition, the X-axis and Z-axis design of the wear-resistant piece and the surface quenching process of the guide rail improve the wear resistance of the ram surface, while extending the service life of the guide rail and maintaining high precision.

The equipment integrates machine, electricity and liquid, presents a compact circular protective structure, effectively reduces the floor space, facilitates transportation and installation, and also saves the time period of installation and debugging. In the beam and vertical tool holder, the position of grating ruler is reserved to ensure the precise control of the equipment.

In order to meet the needs of different users, the equipment provides a variety of optional accessories, such as Yantai Global Tool Table and 12-station follow-up tool magazine. The addition of these optional accessories not only improves the processing efficiency of the equipment, but also further improves the performance and scope of the equipment.

In general, the equipment not only has efficient and stable working performance, but also embodies the humanized design concept and excellent manufacturing process. Whether it is the purchase of new equipment or the upgrading of existing equipment, it is an ideal choice.

|

Serial Number |

Main technical parameters |

Model Unit |

VTL1000 |

VTL1200 |

VTL1600 |

VTL2000 |

VTL2500 |

VTL3000 |

VTL3500 |

VTL4000 |

VTL4500 |

VTL5000 |

VTL5500 |

|

1 |

Table diameter |

mm |

1000 |

1250/1400 |

1600/1800 |

2000 |

2500 |

3000 |

3500 |

4000 |

4500 |

5000 |

5500 |

|

2 |

Maximum swing diameter |

mm |

1250 |

1600 |

2000 |

2500 |

3000 |

3500 |

4000 |

4500 |

5000 |

5500 |

6000 |

|

2 |

Max. turning diameter |

mm |

1250 |

1600 |

2000 |

2500 |

3000 |

3500 |

4000 |

4500 |

5000 |

5500 |

6000 |

|

3 |

Max. workpiece height (H) |

mm |

1000 |

1200 |

1200 |

1400/1600 |

2000/2500 |

2000/2500 |

2500/3100 |

2500/3100 |

2500/3100 |

2500/3100 |

2500/3100 |

|

4 |

Max. workpiece weight (W) |

t |

5 |

8 |

12 |

16 |

20 |

20 |

32 |

32 |

32 |

50 |

50 |

|

5 |

Maximum cutting force of vertical tool holder |

kN |

20 |

20 |

25 |

25 |

35 |

35 |

35 |

35 |

35 |

35 |

35 |

|

6 |

Maximum torque of table |

KN.m |

10 |

12.5 |

20 |

25 |

32 |

32 |

50 |

50 |

80 |

80 |

80 |

|

7 |

Table speed series |

Stepless second gear |

Stepless second gear |

Stepless second gear |

Stepless second gear |

Stepless second gear |

Stepless second gear |

Stepless second gear |

Stepless second gear |

Stepless second gear |

Stepless second gear |

Stepless second gear |

|

|

8 |

Working table speed range |

mm/min |

1-350 |

1-300 |

1-250 |

1-200 |

1-160 |

1-160 |

1-80 |

1-80 |

1-50 |

1-50 |

1-50 |

|

9 |

Series of feed of vertical tool holder |

stepless |

stepless |

stepless |

stepless |

stepless |

stepless |

stepless |

stepless |

stepless |

stepless |

stepless |

|

|

10 |

Vertical tool holder feed range |

mm/min |

1-1000 |

1-1000 |

1-1000 |

1-1000 |

1-1000 |

1-1000 |

1-1000 |

1-1000 |

1-1000 |

1-1000 |

1-1000 |

|

11 |

Fast moving speed of tool holder |

mm/min |

10000 |

10000 |

10000 |

10000 |

6000 |

6000 |

6000 |

6000 |

6000 |

6000 |

6000 |

|

12 |

Vertical travel of vertical tool rest ram (Z-axis) |

mm |

800 |

800 |

1000 |

1000 |

1250 |

1250 |

1400 |

1400 |

1400 |

1400 |

1400 |

|

13 |

Ram section |

mm |

200 × 200 |

200 × 200 |

220 × 220 |

220 × 220 |

240 × 240 |

240 × 240 |

240 × 240 |

240 × 240 |

240 × 240 |

240 × 240 |

240 × 240 |

|

14 |

The ram can pass through the smallest diameter |

mm |

Φ300 |

Φ300 |

Φ320 |

Φ320 |

Φ350 |

Φ350 |

Φ350 |

Φ350 |

Φ350 |

Φ350 |

Φ350 |

|

15 |

Number of tools the magazine can hold |

Put |

12 |

12 |

12 |

12 |

12 |

12 |

12 |

12 |

12 |

12 |

12 |

|

16 |

hilt form |

BT50 |

BT50 |

BT50 |

BT50 |

BT60 |

BT60 |

BT60 |

BT60 |

BT60 |

BT60 |

BT60 |

|

|

17 |

Tool size |

mm |

□ 32 |

□ 32 |

□ 32 |

□ 32 |

□ 32 □ 40 |

□ 32 □ 40 |

□ 32 □ 40 |

□ 32 □ 40 |

□ 32 □ 40 |

□ 32 □ 40 |

□ 32 □ 40 |

|

18 |

Feed motor torque (X/Z) |

M.m |

22 |

22 |

22/27 |

22/27 |

30 |

30 |

40/30 |

40/30 |

40/30 |

40/30 |

40/30 |

|

19 |

Feed motor power (X/Z) |

kW |

3.55 |

3.55 |

3.55/4 |

3.55/4 |

5.5 |

5.5 |

6.4/5.5 |

6.4/5.5 |

6.4/5.5 |

6.4/5.5 |

6.4/5.5 |

|

20 |

Maximum travel of beam |

mm |

750 |

1000 |

1000 |

1200 |

1500 |

1500 |

2100 |

2100 |

2100 |

2100 |

2100 |

|

21 |

Main motor power (AC servo) |

kW |

37 |

37 |

45 |

45 |

66 |

66 |

66 |

66 |

90 |

90 |

90 |

|

22 |

Beam lifting motor power |

kW |

2.2 |

2.2 |

5.5 |

7.5 |

11 |

11 |

18.5 |

18.5 |

18.5 |

18.5 |

18.5 |

|

23 |

Total power capacity |

kVA |

50 |

50 |

62 |

65 |

95 |

95 |

100 |

100 |

125 |

125 |

125 |

|

24 |

Machine weight |

T |

17 |

20 |

28 |

34 |

48 |

55 |

76 |

83 |

90 |

102 |

115 |

|

Standard configuration: ※ manual four-jaw chuck worktable ※ CNC system (SINUMERIK 828D) ※ electric cabinet air conditioner ※ twelve-station tool magazine ※ cooling system ※ maintenance tools ※ standard tool holder 2 ※ work lighting ※ spindle encoder ※ protective cover ※ three-color signal lamp ※ chip conveyor, iron scrap trolley ※ X-axis telescopic protective cover Lubrication and cooling system of ※ foundation foot, pad iron ※ table ※ automatic forced lubrication system ※ beam positioning system (except VTL1000 and VTL1200) |

Options: ※ tool set ※ CNC system (FANUC OI TF) ※ on-line measurement of workpieces ※ three-jaw self-centering hydraulic chuck ※ spindle motor power increase ※ whole machine fully enclosed protection ※ X-axis grating ruler ※ with electric knife table ※ oil-water separator ※ Z-axis grating ruler ※ auxiliary tool holder (left vertical tool holder) ※ workpiece height increase ※ table diameter increase ※ grinding function ※ Z-axis travel increases ※ C- axis indexing ※ the number of ATC tool magazine to increase the ※ milling function |

||||||||||||

|

Structural features: 1. The main drive adopts AC servo main motor, which drives the large gear ring through the gearbox to make the worktable get the corresponding speed, and the main drive speed is controlled by solenoid valve. All gears in the gearbox adopt high frequency quenching grinding process. 2. The form of worktable guide rail is rolling guide rail. The worktable assembly adopts domestic high-precision double-row short cylindrical roller bearing centering in the radial direction and domestic high-precision thrust roller bearing as rolling guide rail in the axial direction. Preloading is added in the axial direction, which not only ensures the rotation accuracy of the worktable assembly, but also improves the carrying capacity of the machine tool. 3. The basic parts of this machine tool are of integral casting structure, which are made of high-strength and low-stress cast iron. After casting, simmer, rough machining and aging treatment are carried out. The column guide rail is ground, and the beam guide rail and ram guide rail are ground after intermediate frequency quenching. 4. The horizontal and vertical feed of the vertical tool holder are all sliding guide rails (hard rails), and the matching guide rails are attached with imported high-strength polytetrafluoroethylene soft belts. The transmission form of the vertical tool holder is all driven by ball screw pair, which is driven by servo motor and directly connected with ball screw through reducer. Vertical tool holder with balance cylinder. |

|||||||||||||

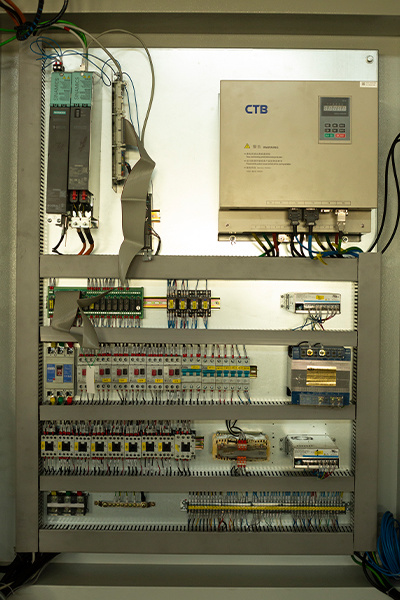

Operation Panel

|

|

|

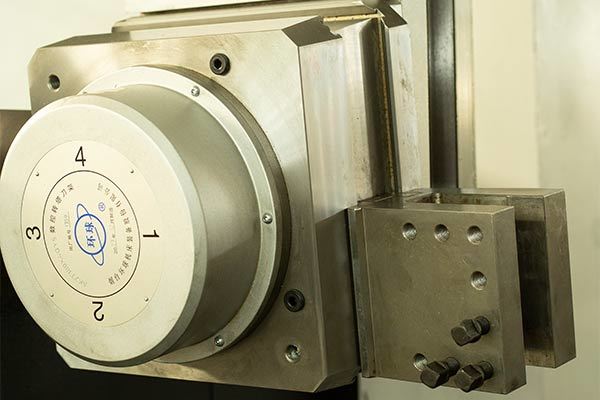

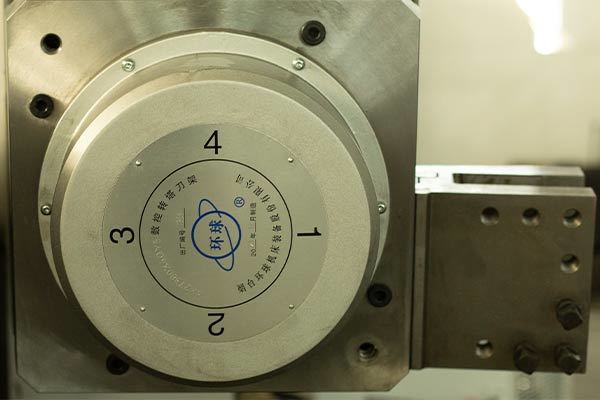

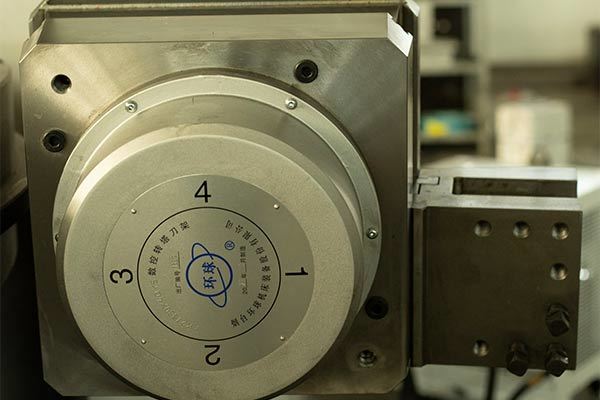

Knife table

|

|

|

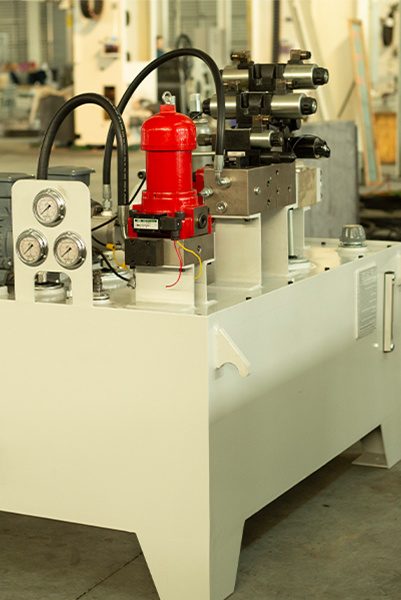

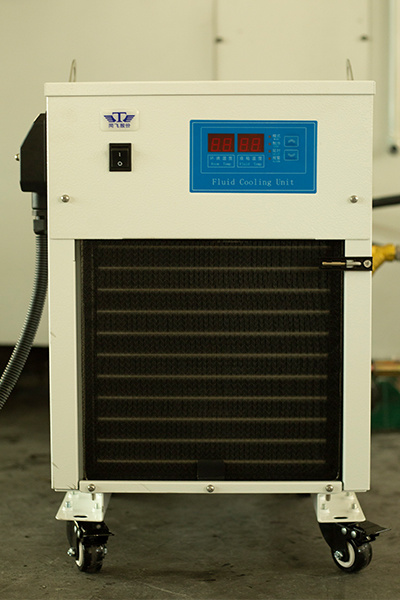

More details

|

|

|

|

|

Related Products