2-axis single column vertical lathe

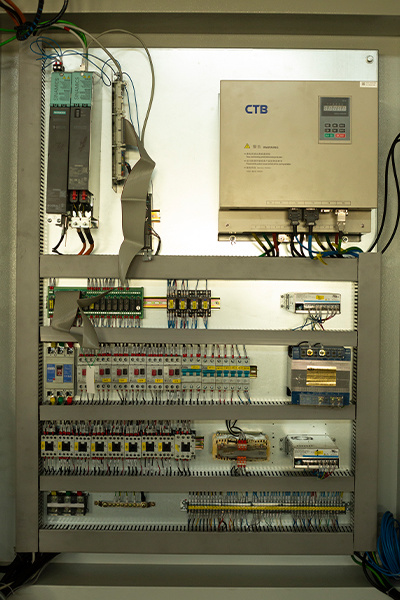

The machine is controlled by Siemens numerical control system. The X-axis and Z-axis are driven by AC servo motor. The main drive is driven by a set of horizontal spindle servo motor. The main motor and the main transmission box are driven by variable speed through horizontal axis mechanism to realize the required rotating speed range during turning. The encoder is equipped in the middle of the spindle to realize constant linear speed cutting. The machine is equipped with a fully enclosed protection around the machine to ensure safe operation and efficient production.

Key words:

Category:

CK51E Series

Product Details

The machine is controlled by Siemens numerical control system. The X-axis and Z-axis are driven by AC servo motor. The main drive is driven by a set of horizontal spindle servo motor. The main motor and the main transmission box are driven by variable speed through horizontal axis mechanism to realize the required rotating speed range during turning. The encoder is equipped in the middle of the spindle to realize constant linear speed cutting. The machine is equipped with a fully enclosed protection around the machine to ensure safe operation and efficient production.

The machine tool is designed and manufactured with advanced cast iron and box structure. The X and Z axis guide rails are made of wear-resistant guide rails and hard rail structure. The guide rail surface is quenched and ground to improve the wear resistance of the ram and beam surface. The guide rail has high service life and high precision retention;

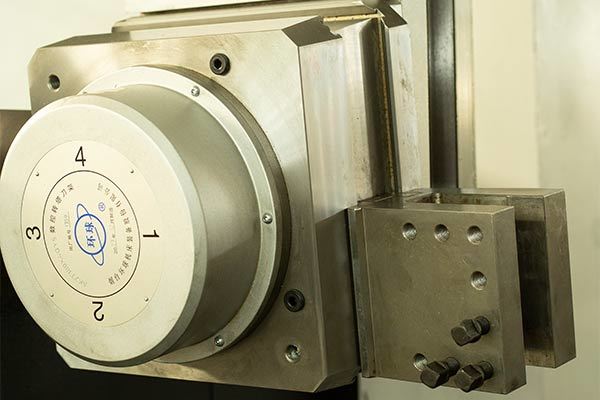

The vertical tool holder can move horizontally on the beam and the ram can move vertically. The motor and the ball screw can be directly connected through the flexible coupling to cut any complex rotary surface, and can control the continuous trajectory.

The machine is suitable for machinery manufacturing, automobile manufacturing, wind power energy, aerospace, military, train wheels, ships and other fields. Precision machining of inner and outer cylindrical surfaces, conical surfaces, planes, grooving, cutting, turning threads and rotary surfaces of disc, ring and rotary parts.

|

Serial Number |

Main technical parameters |

Model |

CK518E |

CK5112E |

CK5116E |

CK5120E |

|

Unit |

||||||

|

1 |

Table diameter |

mm |

800 |

1010 |

1400 |

1800 |

|

2 |

Maximum swing diameter |

mm |

950 |

1250 |

1600 |

2000 |

|

2 |

Max. turning diameter |

mm |

800 |

1250 |

1600 |

2000 |

|

3 |

Max. workpiece height (H) |

mm |

800 |

1000 |

1000 |

1250 |

|

4 |

Max. workpiece weight (W) |

t |

2 |

5 |

8 |

12 |

|

5 |

Maximum cutting force of vertical tool holder |

kN |

20 |

20 |

25 |

25 |

|

6 |

Maximum torque of table |

KN.m |

6 |

12.5 |

17.5 |

20 |

|

7 |

Table speed series |

|

Stepless second gear |

Stepless second gear |

Stepless second gear |

Stepless second gear |

|

8 |

Working table speed range |

mm/min |

1-315 |

1-250 |

1-200 |

1-125 |

|

9 |

Series of feed of vertical tool holder |

|

stepless |

stepless |

stepless |

stepless |

|

10 |

Vertical tool holder feed range |

mm/min |

1-500 |

1-500 |

1-500 |

1-500 |

|

11 |

Fast moving speed of tool holder |

mm/min |

2000 |

2000 |

2000 |

2000 |

|

12 |

Vertical travel of vertical tool rest ram (Z-axis) |

mm |

650 |

650 |

800 |

800 |

|

13 |

Ram section |

mm |

180 × 180 |

180 × 180 |

200 × 200 |

200 × 200 |

|

The ram can pass through the smallest diameter |

mm |

Φ260 |

Φ260 |

Φ290 |

Φ290 |

|

|

14 |

Ram section |

mm |

330 × 210 |

330 × 210 |

350 × 215 |

350 × 215 |

|

The ram can pass through the smallest diameter |

mm |

Φ530 |

Φ530 |

Φ540 |

Φ540 |

|

|

15 |

Tool size |

mm |

□ 40 |

□ 40 |

□ 40 |

□ 40 |

|

16 |

Feed motor torque (X/Z) |

M.m |

11 |

11 |

15/11 |

15/11 |

|

17 |

Feed motor power (X/Z) |

kW |

1.75 |

1.75 |

2/1.75 |

2/1.75 |

|

18 |

Maximum travel of beam |

mm |

550 |

750 |

760 |

1000 |

|

29 |

Main motor power (AC servo) |

kW |

22 |

30 |

37 |

37 |

|

20 |

Beam lifting motor power |

kW |

2.2 |

2.2 |

2.2 |

2.2 |

|

21 |

Total power capacity |

kVA |

32 |

40 |

47 |

50 |

|

22 |

Overall dimension |

mm |

4020 × 3150 × 3700 |

5200 × 3250 × 4380 |

5510 × 3925 × 4600 |

6310 × 4200 × 4900 |

|

23 |

Machine weight |

T |

10 |

12 |

15 |

20 |

|

Standard configuration: |

Options: |

|||||

|

Manual four-jaw chuck table |

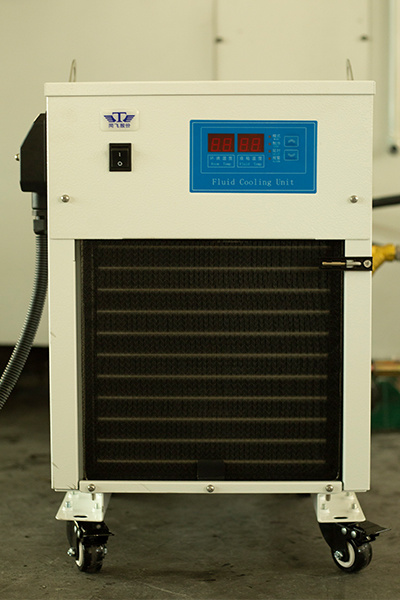

Electric cabinet air conditioner |

CNC 系统(FANUC OI TF) |

||||

|

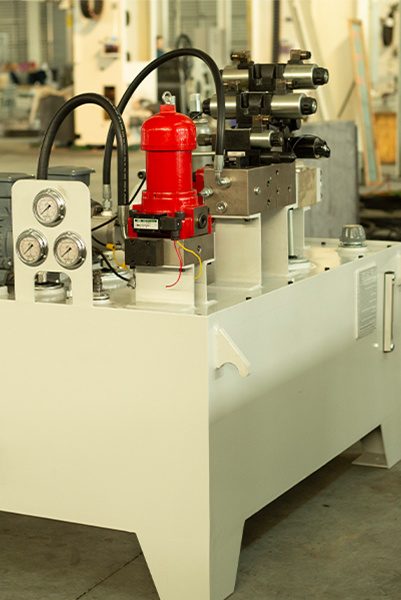

Cooling system |

spindle encoder |

CNC 系统(SINUMERIK 828D) |

||||

|

Standard knife holder 2 |

Working lighting |

Oil-water separator |

||||

|

Protective cover |

Three-color signal lamp |

Increased Z-axis travel |

||||

|

Chip conveyor and scrap iron trolley |

X-axis telescopic protective cover |

Three-jaw self-centering hydraulic chuck |

||||

|

Foundation feet, pads |

Spindle motor power increase |

|||||

|

automatic forced lubrication system |

Vertical tool holder form |

|||||

|

Maintenance tools |

Workpiece height increases |

|||||

|

CNC 系统(SINUMERIK 808D) |

||||||

|

Table lubrication cooling system |

||||||

Operation Panel

|

|

|

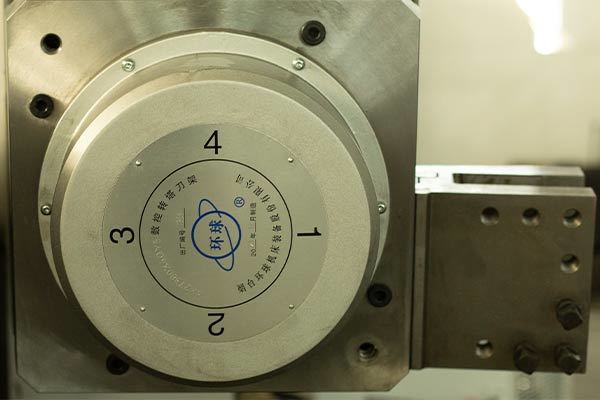

Knife table

|

|

|

More details

|

|

|

|

|

Related Products